Our country pages

Africa

Europe

Search

Order a sample

You can order up to 3 free sample tiles.

We'll aim to deliver your sample order within 5-7 working days from your order date.

SBS vs APP Roofing explained

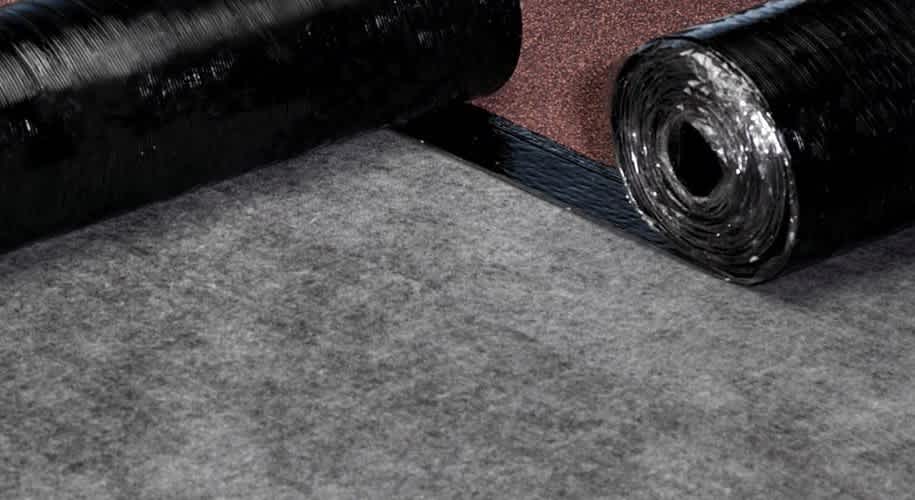

Modified bitumen

Not all bitumen is created equally. The original discovery of bitumen made from oil in ancient times means that it has been used in roads and roofing for thousands of years. Bitumen and limestone are mixed to create asphalt which reduces viscosity and strengthens the material.

As the construction industry has evolved, bitumen itself has transformed – with new materials added to bitumen to create “modified bitumen” that solves specific challenges.

The main two modified bitumen materials are SBS and APP. SBS stands for styrene-butadiene-styrene and APP for a-tactic polypropylene. But what does modifying bitumen with each of these materials achieve and why are they so popular?

Jump to section

SBS bitumen

SBS is bitumen that has elastomer added by way of the rubbery substance styrene-butadiene-styrene. This elasticity allows it to absorb the movement of underlying materials and insulation as it can stretch to accommodate them. It also means SBS can flex under wind and weather stresses including the expansion and contraction British homes tend to experience at the change of seasons. Conversely, the same elasticity means that the membrane is not as effective at resisting UV rays as other bitumen and as such is not suitable for countries with hotter climates.

Using a torch-on version of SBS for installers means a somewhat trickier installation thanks to its melt-resistance, but the final aesthetic is generally seen as superior. Instead of melting into liquid like some roofing membranes, SBS becomes a sticky melt that can be applied with less heat. However, less experienced roofers may overheat the membrane creating an excessive bleed and causing the finished surface to warp. SBS is also the material of choice for hot melt applications which are still a popular choice for inverted systems.

Ultimately, SBS-modified bitumen offers good resistance to both weight and weather. It tends not to age or oxidise and is therefore a popular choice in the UK.

APP bitumen

APP-modified Bitumen instead uses the plastic atactic polypropylene, which is melted with a torch into a liquidy wax at 300F. It has a very high temperature tolerance and is appreciated for its ease of installation. When time is a factor, APP is often the best choice for quick installation as less attention to detail is required in the heating of the membrane.

APP is typically chosen in hotter climates as it has higher temperature flexibility when compared to SBS. Unfortunately, APP does not offer the same ability to flex as SBS and is therefore more prone to damage and surface cracks.

SBS vs APP

When comparing both systems, it’s important to consider the job. SBS-modified bitumen is, as discussed, more difficult to install – but it is also more malleable and can be used in areas that need flexibility such as on a wall flashing. APP bitumen is prefered if you need a straightforward bitumen solution that can be installed quickly and efficiently by roofers who may not be highly skilled. SBS offers more longevity and durability but has a less forgiving installation process.

APP is an imported product, whereas SBS is manufactured in the UK and has lower temperature flexibility and durability, making it perfect for colder climates such as the UK. It is a consistent material that can be relied on time and time again – and for that reason is the system of choice for experienced roofers in the UK.

Technical Services

Technical Services

Our team of experienced roofing specialists can help you to identify the best solution for your roofing project Tel: 0330 123 4585 or email technicaluk@bmigroup.com